The Ultimate Guide to ERP Transformation: How Process Mining Prevents Million-Dollar Failures

- Oct 20, 2025

- 5 min read

Here's a sobering statistic that should make every CEO pause: over 70% of ERP transformations fail to deliver their promised value, with individual projects losing companies upwards of $580 million. That's not a typo: we're talking about more than half a billion dollars disappearing because organisations transformed their systems without understanding their processes.

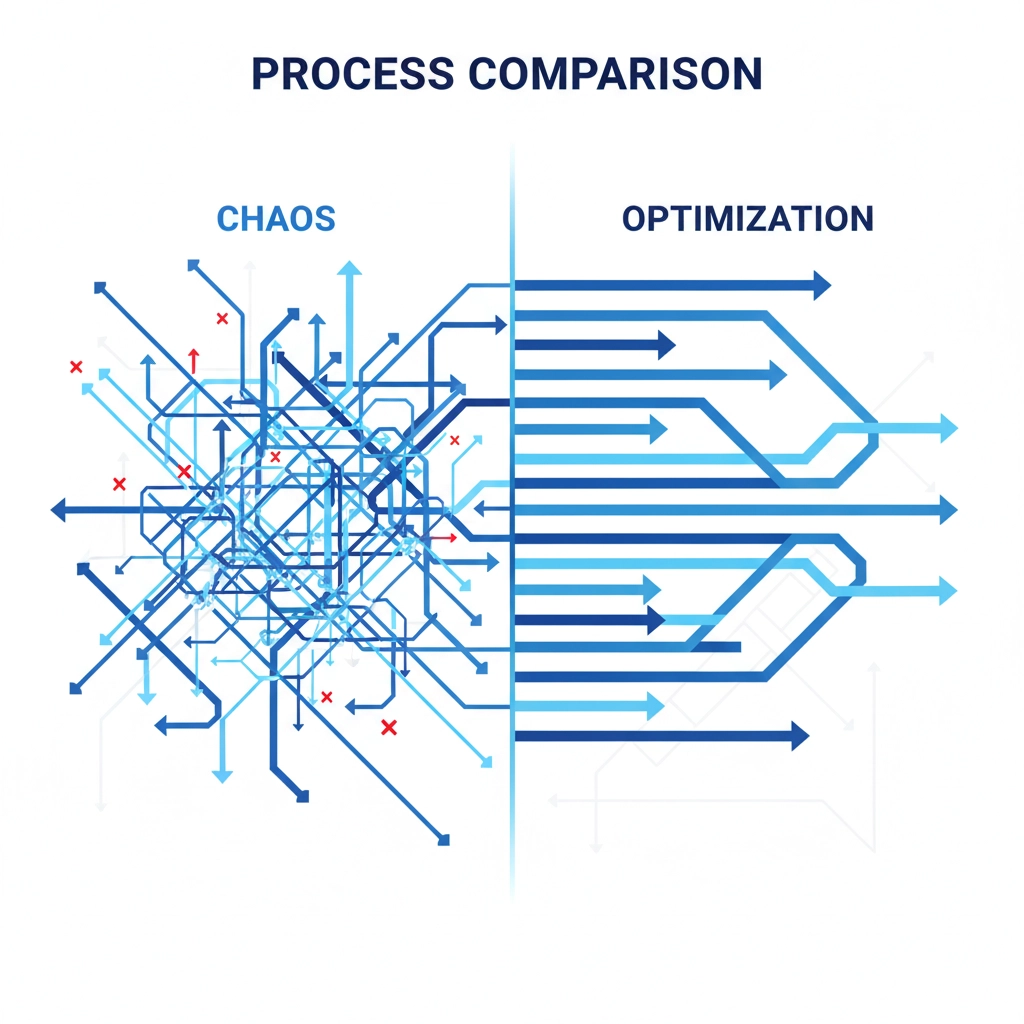

The brutal truth? Most ERP failures aren't caused by bad software or incompetent consultants. They happen because companies migrate broken processes into shiny new systems, essentially automating dysfunction at enterprise scale. Process mining has emerged as the antidote to this epidemic of expensive failures, providing the evidence-based foundation that successful transformations require.

Why ERP Transformations Keep Failing

The core problem with most ERP implementations is deceptively simple: organisations don't actually know how their processes work. They think they do, but reality tells a different story.

Traditional process mapping relies on interviews, workshops, and documentation reviews. These methods capture what people think happens, not what actually happens. By the time you've mapped processes across departments and geographies, the insights are already outdated, and you've missed the informal workarounds that keep operations running.

Here's what typically goes wrong: A mining company decides to implement SAP S/4HANA across their operations. They spend months in workshops documenting the "current state" of their procurement processes. What they don't capture are the dozens of email-based approvals, spreadsheet workarounds, and manual data entry steps that bypass the official system. When go-live happens, these undocumented processes break, creating operational chaos that can take months to resolve.

The financial impact compounds quickly. Beyond the direct cost of fixes and delays, there's lost productivity, supplier relationship damage, and the opportunity cost of senior management attention diverted from strategic initiatives. One resources company I worked with estimated their failed ERP implementation cost them $43 million in direct expenses and another $20 million in lost productivity over two years.

How Process Mining Changes the Game

Process mining fundamentally shifts ERP transformation from guesswork to evidence-based decision making. Instead of asking people how processes work, it extracts actual event data from your existing systems: every transaction, every timestamp, every user interaction: and algorithmically reconstructs what really happens.

This approach reveals operational reality in granular detail. You see every step of every process, including all variations, exceptions, and workarounds. More importantly, you see the business impact of each deviation: which variations create delays, which workarounds introduce compliance risks, and which processes are stable enough for automation.

The methodology follows four distinct phases that align perfectly with ERP transformation requirements:

Discovery Phase: Mapping Reality Process mining extracts event logs from your transactional systems and reconstructs actual process flows. This isn't theoretical mapping: it's empirical evidence of how work actually moves through your organisation. You discover the "happy path" (most efficient route) and every deviation that creates waste or delays.

Analysis Phase: Understanding Impact The technology quantifies the business impact of process variations. Which procurement workarounds cost you money? Where do compliance gaps exist? Which processes have too much variation to automate safely? These insights directly inform your ERP design decisions.

Optimisation Phase: Targeted Improvements Armed with data, you can execute targeted enhancements before migration. Fix broken processes, standardise variations, and eliminate unnecessary complexity. The critical difference is that improvements are simulated before implementation, so you understand their likely impact.

Monitoring Phase: Sustaining Value Process mining transforms improvement from a one-time project into an ongoing capability. Continuous monitoring ensures your ERP investment keeps delivering value years after go-live, catching process drift before it becomes expensive.

A Framework That Actually Works

The most successful ERP transformations I've seen follow a specific process intelligence framework that prevents the common failure modes:

Pre-Migration Process Audit Before touching your ERP system, conduct a comprehensive process mining assessment. Identify process variations that need harmonisation, workarounds that must be eliminated, and compliance gaps that could undermine the transformation. This becomes your transformation insurance policy.

Data-Driven Design Decisions Use process mining insights to inform your ERP configuration. Instead of guessing which processes need customisation, you have evidence of which variations add value and which create waste. This dramatically reduces over-engineering and scope creep.

Simulation and Risk Assessment Model your proposed changes before implementation. Process mining allows you to simulate different scenarios and understand their likely impact on performance, compliance, and user experience. This capability alone prevents millions in costly redesigns.

Change Management with Evidence Process mining provides the factual foundation for change management. Instead of telling people their processes will improve, you can show them exactly how, with specific metrics and timelines. This evidence-based approach dramatically improves adoption rates.

Real-World Application: Mining Sector Success

Consider a Western Australian mining company facing a critical SAP S/4HANA migration across their supply chain operations. Traditional process mapping would have taken 18 months and missed critical workarounds. Instead, they deployed process mining across their procurement, inventory, and maintenance systems.

The results were revelatory. They discovered their procurement process had 47 different variations, many involving manual approvals that bypassed the ERP system entirely. Some variations took 3 days to complete purchase orders, while others took 47 days for identical transactions. The process mining analysis revealed that 23% of all transactions involved workarounds that introduced compliance risks.

For example, a major Australian resources company recorded approximately AU$233 million in cumulative lost potential revenue over a 10-year period due to maintenance shutdown overruns. Repeatedly, critical maintenance parts did not arrive on time, extending plant downtime and wiping out valuable operating hours—directly reducing ore output and overall revenue. This is a vivid illustration of how process blind spots in maintenance and supply chain handoffs create enormous losses. Process mining identifies and quantifies these gaps by tracing the real flow across maintenance planning, procurement, suppliers, warehousing, and logistics—pinpointing issues like late purchase requisitions, unconfirmed purchase orders, delivery slippage, and pick/issue bottlenecks—so teams can redesign the end-to-end process and keep shutdowns tight before and after ERP go-live.

Armed with this evidence, they redesigned their processes before migration, standardising workflows and eliminating unnecessary variations. The ERP transformation delivered measurable results: 40% reduction in procurement cycle times, 60% fewer exceptions requiring manual intervention, and 100% compliance with internal controls. Total project savings exceeded $11 million compared to their original budget, and go-live happened on schedule.

Actionable Steps for Your ERP Transformation

Here's your roadmap for applying process intelligence to prevent ERP failure:

The organisations that succeed with ERP transformation share one characteristic: they ground their decisions in operational reality rather than wishful thinking. Process mining provides that reality, transforming ERP projects from expensive gambles into evidence-based investments that deliver predictable returns.

Your ERP transformation doesn't have to join the 70% that fail. With process intelligence as your foundation, you can design changes that stick, scale automation with confidence, and monitor performance long after go-live. The technology exists, the methodology is proven, and the results speak for themselves.